dgdf hfg        Always a good choice if high pressure and high performance is needed High quality wear resistant components

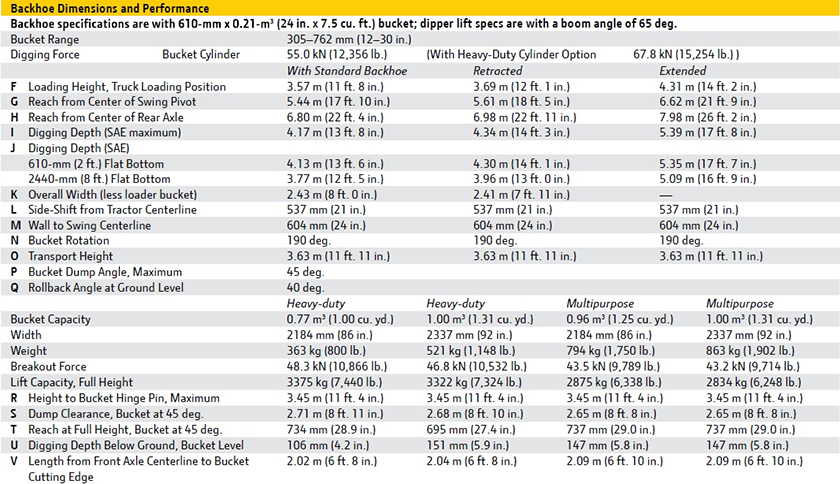

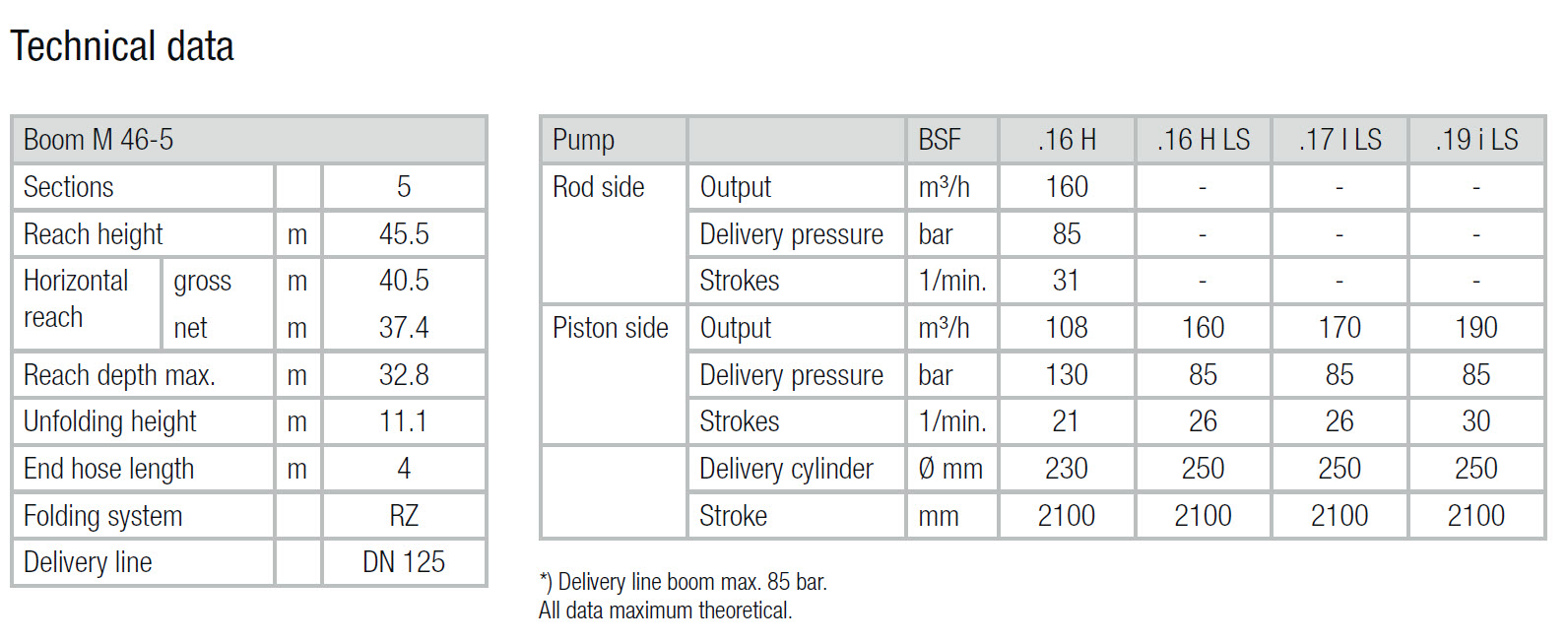

The world-record setting long stroke concrete pump with high performance For virtually all high-rise projects the ideal machine. With this machine you are on the safe side. Pressure and output is guaranteed for almost all applications

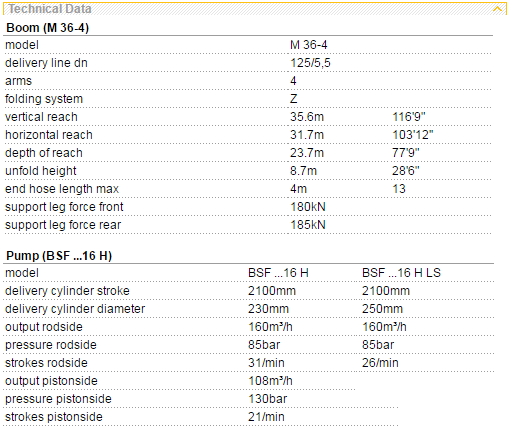

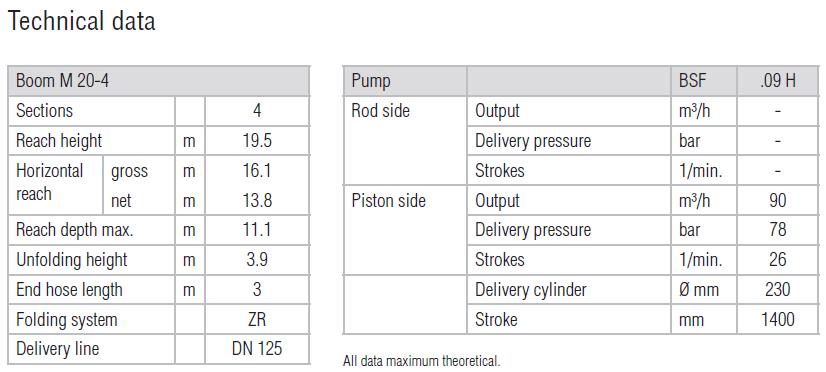

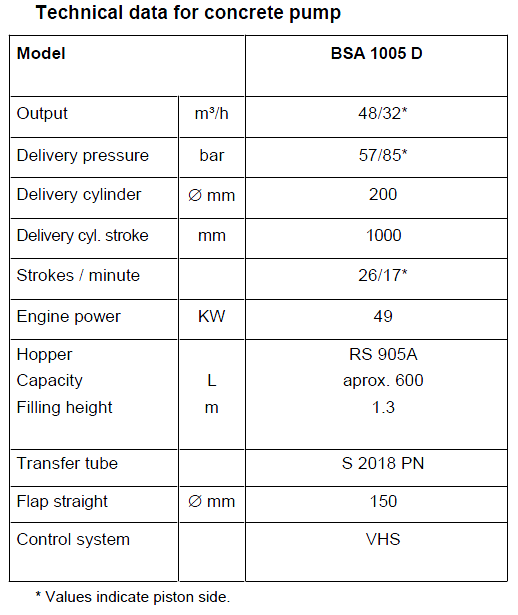

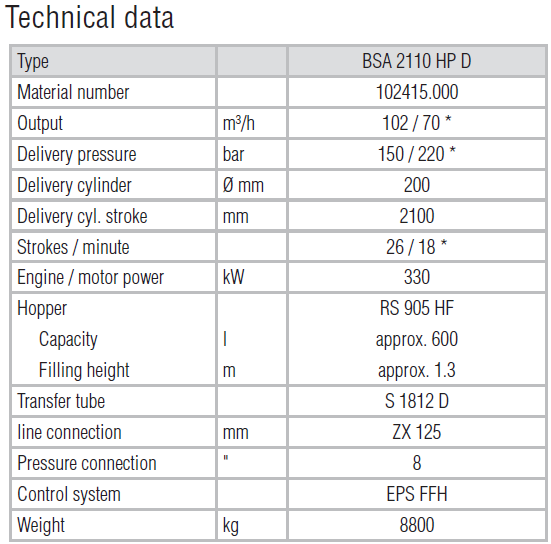

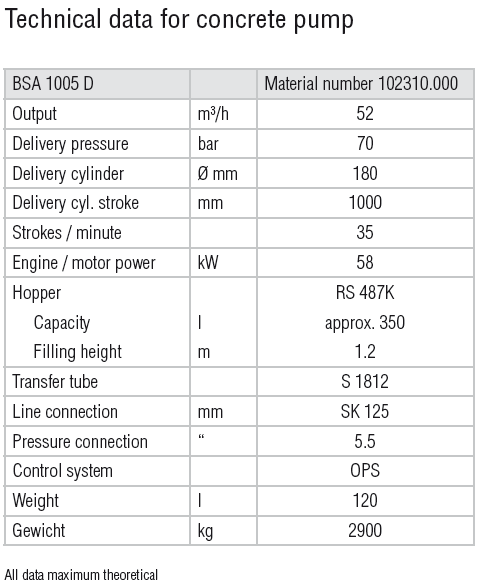

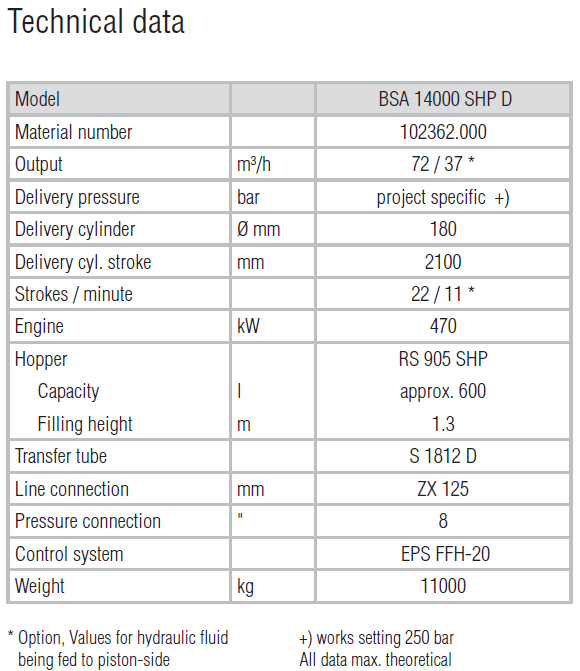

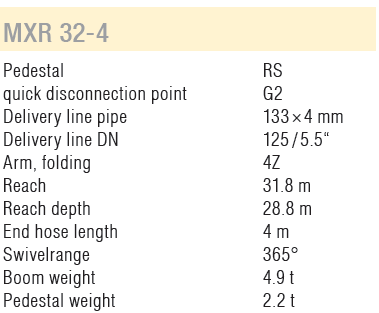

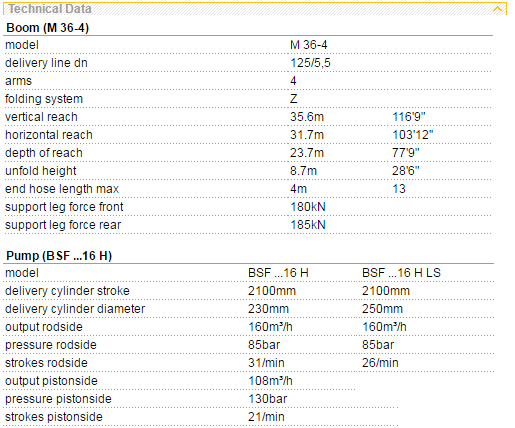

(Not authorized for Europe and USA! For this see: BSA 2110 HP D4). The BSA 2110 is an all-rounder for medium distance with a vertical reach from 100 m to 300 m and a horizontal reach about 1000 m. Diesel-powered with an exhaust-stage 3A.  The compact, quiet, multi-purpose concrete pump. Equipped with the new OPS 10 control and EPS, the successor of the fully hydraulic control (VHS). EPS (Ergonic Pump System) enables a particularly smooth switchover of the S transfer tube while reducing wear at the same time. With the BSA 1005 D, it is possible to deliver normal concrete with a grain size of up to 32 mm.  The high performance pump for which there are almost no limits. The ideal pump for extreme jobsites for high-rise and long distance pumping. Equipped with piston pump 2100 x 180 mm, Output up to 71 m³/h, pressure up to 400 bar (theor. max.)  Stationary Placing boom MXR 32-4 Multi Feature

Benefit

Stationary Placing boom MXR 36-4 Multi Feature

Benefit

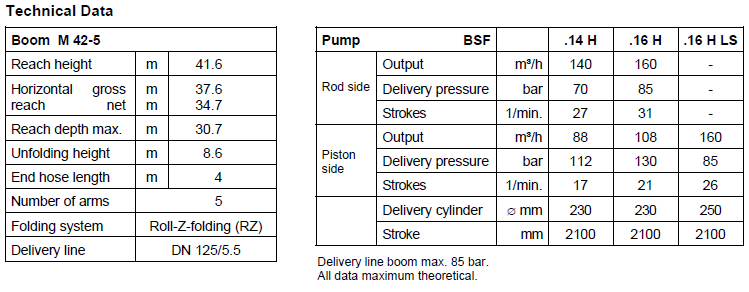

Stationary Placing boom MXG 42-5 Multi Feature

Benefit

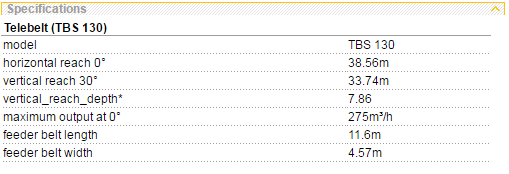

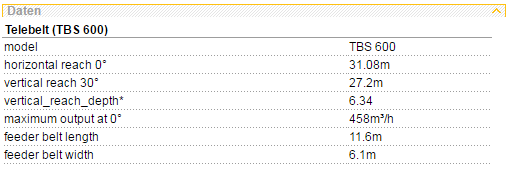

Semi-trailer Telescopic Belt Conveyor

Semi-Trailer Advantages: Maneuverable 5th wheel trailer configuration

Chassis versatility

Material placement does not rely on the chassis engine

Application flexibility

Semi-trailer Telescopic Belt Conveyor

Semi-Trailer Advantages: Maneuverable 5th wheel trailer confi guration

Material placement does not rely on the chassis engine

Application flexibility

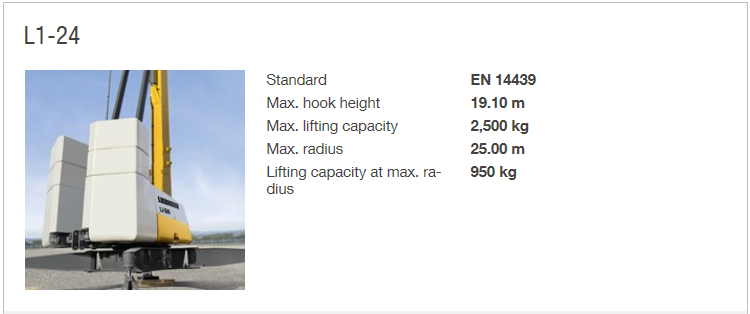

เครื่องพ่นปูนฉาบ PUTZMEISTER ( BRAND : GERMANY ) เหมาะสำหรับปูนผสมทราย งานฉาบ งานเกาท์ พ่นฉนวนกันความร้อน คุณภาพงาน 1. ช่วยลดเวลาการทำงาน และขั้นตอนการลำเลียงปูนผสม 2. ลดแรงงานกว่าครึ่ง ลดการสูญเสีย จากการตกหล่นของปูน เครื่องพ่นปูนฉาบ รุ่น MP25 PUTZMEISTER ( BRAND : GERMANY ) เหมาะสำหรับปูนมอร์ต้าร์ สำเร็จรูปได้ทุกยี่ห้อ , ยิปซั่ม , ปูน Gypsum มีปั๊มน้ำ และ ปั๊มลม ติดตั้งในตัวเครื่องพร้อม ตัวเครื่อง : สามารถแยกชิ้นส่วนประกอบได้ 4 ส่วน(เพื่อความสะดวกในการเคลื่อนย้ายไปตามจุดต่างๆ) วงจรป้องกัน ระบบไฟฟ้า : กรณีไฟไม่ครบเฟส ไฟกลับเฟส น้ำขาด เครื่องจะหยุดทำงาน รวมถึง กรณี Overload เช่น สายบล็อกด้วย Sprayboy – mixes, pumps and sprays Refurbishers with small crews should definitely take a closer look at the Sprayboy. It is small, light, versatile and extremely good value for money. It is hard to believe that three functions can be combined in such a compact machine. It can mix, pump or spray – and changing between functions just requires the flip of a switch. The Sprayboy really does have everything you need to help you complete small jobs quickly and profitably. Large machines with masses of power and countless functions are not always the ideal solution. Often a small pump like the Sprayboy is quite sufficient. Example of filling frames – Here, the mixing quality and manageability are particularly important. The Sprayboy masters these both perfectly. And a special frame filling hose is used to fill the cavities between the wall and frame. Example of injecting and setting anchors – Anchor elements are used to stabilise walls, ceilings, tunnels, etc. Here, you can use the Sprayboy to perfectly fill the drill holes and fix the anchors. This can be done with or without using pressure. Example of fire protection mortar – When cable fire breaks or pipe shafts are being sealed, speed is of the essence, as fire protection mortar sets within a very short space of time. The Sprayboy mixes the fire protection mortar to the optimum quality. Then you pump it through a flexible hose into the openings and fill the cavities. We also recommend the frame filling hose or frame filling device for this application. These are, of course, only three of the many different ways of using the Sprayboy. It‘s best to remember the following simple formula: small job + pumpable mortar = Sprayboy.  L1-Crane : Datasheet ดาวน์โหลด PDF TOWER CRANE & RENTAL. Our range includes machines for all systems and size classes. We have the perfect solution for every construction task. IHI BOILER Compact in size but highly efficient, IHI Packaged Boilers can optimize space efficiency.IHI Packaged Boilers are also well known for its energy and operational... John Deere has acquired the Wirtgen Group which has five premium brands across the road construction sector spanning milling, processing, mixing, paving, compaction, and rehabilitation. This acquisition positions us to better serve the growing need for infrastructure development and improvements worldwide. Once Through Boiler K-LH High Pressure Series LPG/NG Gas Fired, Oil Fired Advanced High Pressure Series with High Quality Demanded by the Modern Age

Gas Fired Once Through Boiler K-Series (With Economizer) LPG/NG Gas Fired Improvement in the heat transfer performance and the wide combustion range technology

K-SE Series High Efficiency  K-1000SE

K-1600SE

K-2000SE

K-2500SE

K-L Series (High Efficiency with K-LE Series)  K-750 (LE)

K-1000 (LE)

K-1600 (LE)

K-2000 (LE)

Small Size Economic Boiler (100 kg/h - 500 kg/h)  K-100Q

K-200Q

K-300Q

K-500Q

K-1600LH

K-1600LEH (With Economizer)

K-2000LH

K-2000LEH (With Economizer)

Fire Tube Kure Boiler KM Series and High Pressure Gas Fired , Oil Fired and Switchable Gas/Oil Fired Classic Pursuit of Steam Quality

KMH Series

SCM High pressure series

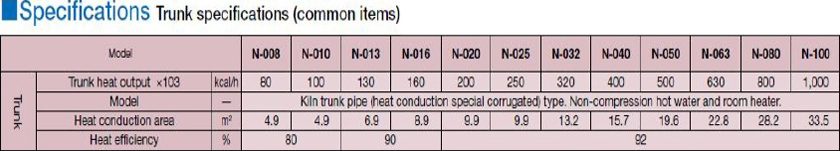

Thermal conduction water (media of full leve) stored in the trunk under atmospheric state is heated below the boiling point and conveys heat indirectly to the independent internal heat exchanger.It is the efficient and simplified structure system to save energ:y and resource that combines the conventional hot water device and the isolated heat exchanger. Applicable to multipurpose use Various uses can be applied to each unit of the built-in isolated heat exchangers. Not onily the 2-circuit (2 purposes) room heater and hot water supply,but also the 3-circuit application if we can attach the circuit for tank circulation to the applliance.  IBD System IHI Boilers Development System IHI proudly brings the "IBD System", which provides even more effective use of multiple installation of small, high-efficiency once through boiler system that are manufactured using advanced technologies. This system helps with the rationalization, energy saving, labor saving, and automation of customers' steam system.  For rationalized boiler management - Features A system which makes it possible to simultaneously monitor and automatically prepare daily/monthly/yearly reports using a personal computer. Featuring an abundance of function from the viewpoint of the person in charge of control.

- Monitoring function - Daily/monthly/yearly report function - Operation help function (alarm guidance display) - Data backup function using an external HDD For efficient multiple installation boiler - IHI's patented new method - Also support Blue-i SYSTEM - Constant pressure control system (patented) - Controls up to 32 unit Control even possible with a mix of three stage combustion and four stage combustion boilers. - Arbitrary operation sequence can be set Operation sequence and status (base boiler, standby boiler, etc.) - Equipped with a cyclic function Equalization of the stop/start count of each boiler - Forced low combustion function Forces low combustion of boilers which have stopped for a certain period of time in order to speed up steaming and for boiler tube protection purposes, thus maintaining a state close to a hot condition. - Mid-purge backup function Until the boiler receives a start signal and ignites, the boiler immediately upstream in the sequence which is in a low combustion state switches over to steam pressure during purge.  The steam from each boiler is gathered in one steam header, and then supplied to where it is needed. The multi-boiler control system detects the steam header pressure using a sensor and outputs combustion command signals (combustion stop, low combustion, middle combustion, high combustion) to each boiler so that the pressure of the steam inside the steam header can be maintained at the pre-set value. IHI developed the constant pressure control system to replace the conventional step type multi-boiler control system.  Energy Saving Equipment  Gas air pre-heater Air Heater By recovering the boiler exhaust gas heat for combustion of air, the boiler efficiency is dramatically improved. There are three types: compact heat heat pipe type, steel pipe type, and rotating regenerator for large capacity type.  Feed Water pre-heater Economizer With asystem that reuses exhaust gas heat for pre-heating feed water, this is designed to increase heat efficiency and provide energy savings. The heat can be recovered without increasing the NOx in the exhaust gas, which prevents emission.  Collect steam and absorb load fluctuations Accumulator Hot water is stored in the accumulator. When there is large amount of steam usage, steam is generated through self-evaporation, which supplements the shortage of steam. This eliminates sudden load fluctuation in the boiler, thus increasing efficiency.  Effective energy-saving measures Drain recovery device A large amount of potential heat remains in the drain, and by recover-ing and reusing this heat, the fuel costs can be greatly reduced. Drain recovery is one of the most effective energy-saving measures available.  Massive energy savings Rotation control device The FDF (forced draft fan) accounts for about 40-70% of the power consumed when operating a boiler. Using a revolving speed control device on the FDF enables great energy savings. (The same energy savings can be seen with an IDF (induced fan).) Furthermore, compared to discharge damper system, the combusion can be adjusted easily, which makes it effective when used as controls for low 02 combusion control device.  Automated manufacturing from load fluctuations Emulsion oil manufacturing device By using microcomputer controls to regulate the amount of water injected, this breakthrough system can continuously manufacture emulsion oil. It creates and combusts emulsion oil depending on the load fluctuation, which improves conbustion efficiency and reduces the amount of dust and soot that is generated.  Recovery of blower watwe heat Continuous blowers By recovering blower water heat in the boiler through heat exchange and reusing it for pre-heating feed water, this manages the boiler water concentration. This is available for a wide range of series, from high pressure, small boiler. We offer a variety of option that meet your needs.  Automatic Water Softener Auto Softener This device removes the elements which makes the feed water hard (calcium, magnesium) and prevents scale build-up inside the boiler so that they may be used for a long period of time.  Fan invertercontrol The Motor rotational speed changes to suit the combustion status, supplying only the necessary amount of air. As such, power consumption is reduced, which in turm reduces rates while suppressing noise at the same time.  Boiler water concentration automatic blow device Detects boiler water concentration using a sensor and automatically controls boiler water concentration with a blow device in order to constantly maintain good steam at the same time as preventing boiler corrosion, carry over and so on.  Chemical feeder A device which continuously injects oxygen scavenger to remove oxygen from feed water as well as boiler compound to create an environment in which steel does not easily corrode.  Ishiclean Ishiclean is a compound chemical for boiler. Ishiclean offers benefits such as PH adjustment, scale build-up prevention, ani-corrosion, removal of dissolved oxygen and sludge dispersion. Stable and high heat efficient boiler operation is possible, greatly contributing to the improvement of economic performance and extension of boiler life.  Feed water tank 25l-5,000l IHI offers a device to heat feed water to 55oC or higher.  Exhaust pipe 120o - 400o  Datasheet ดาวน์โหลด PDF  Datasheet ดาวน์โหลด PDF  Datasheet ดาวน์โหลด PDF  Datasheet ดาวน์โหลด PDF  Datasheet ดาวน์โหลด PDF  Datasheet ดาวน์โหลด PDF  Datasheet ดาวน์โหลด PDF  Datasheet ดาวน์โหลด PDF NK-300VR FULLY HYDRAULIC TRUCK CRANE Maximum lifiting capacity : 30t x 3.0m Maximum boom length : 34.0m Engine output : 213kW/2,300min (ISO Net) Datasheet ดาวน์โหลด PDF NK-600RX FULLY HYDRAULIC TRUCK CRANE Maximum lifiting capacity : 55t x 3.0m Maximum boom length : 43.0m Engine output : 258kW/2,100min (ISO Net) Datasheet ดาวน์โหลด PDF NK-600RX FULLY HYDRAULIC TRUCK CRANE Maximum lifiting capacity : 60t x 2.7m Maximum boom length : 43.0m Engine output : 302kW/1,800min (ISO Net) Datasheet ดาวน์โหลด PDF SR-300L FULLY HYDRAULIC TRUCK CRANE Maximum lifiting capacity : 30t x 3m Maximum boom length : 30.5.0m Engine output : 200kW/2,600min (ISO Net) Datasheet ดาวน์โหลด PDF SR-500L FULLY HYDRAULIC TRUCK CRANE Maximum lifiting capacity : 61t x 2.5m Maximum boom length : 35.0m Engine output : 200kW/2,600min (ISO Net) Datasheet ดาวน์โหลด PDF SR-700L FULLY HYDRAULIC TRUCK CRANE Maximum lifiting capacity : 70t x 2.5m Maximum boom length : 44.50m Engine output : 257kW/2,200min (ISO Net) Datasheet ดาวน์โหลด PDF KA-1300RX ALLTERR Jib lifing capacity

Boom lifting capacity

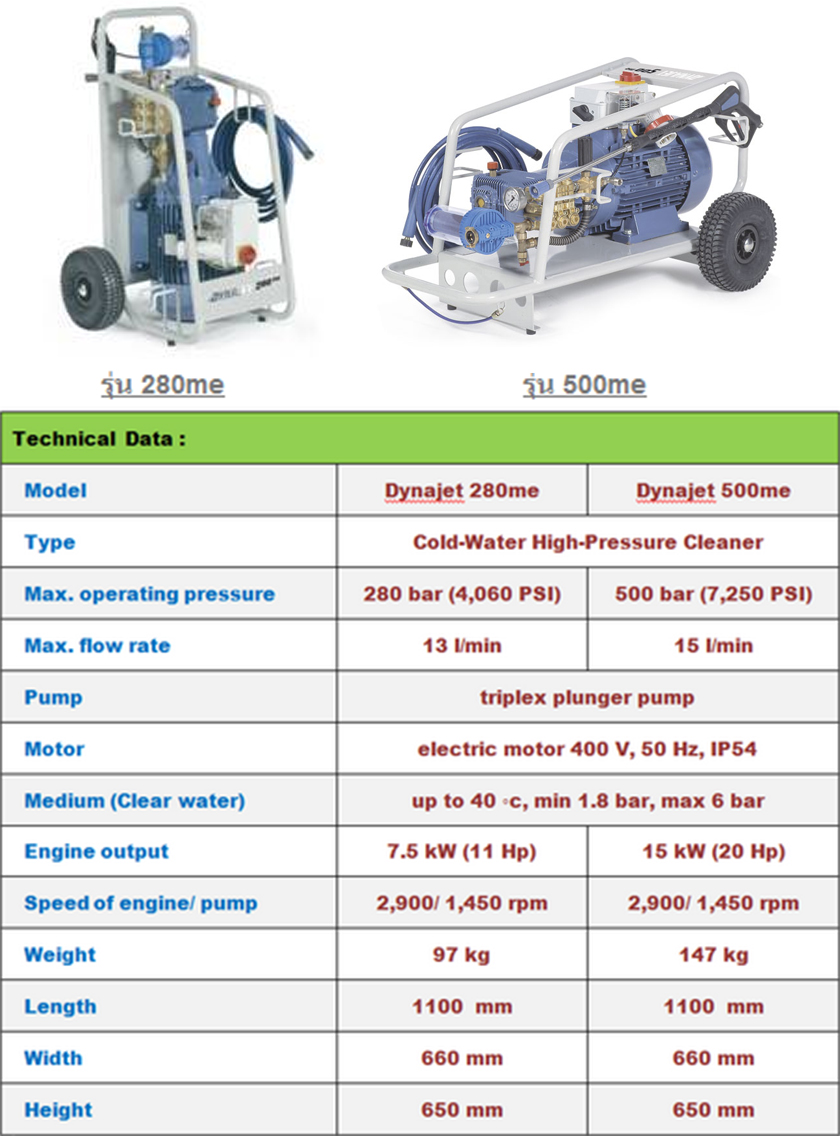

Datasheet ดาวน์โหลด PDF เครื่องฉีดน้ำแรงดันสูง DYNAJET ( BRAND : GERMANY) ใช้ในงาน ระบบไฟฟ้า 3 เฟส

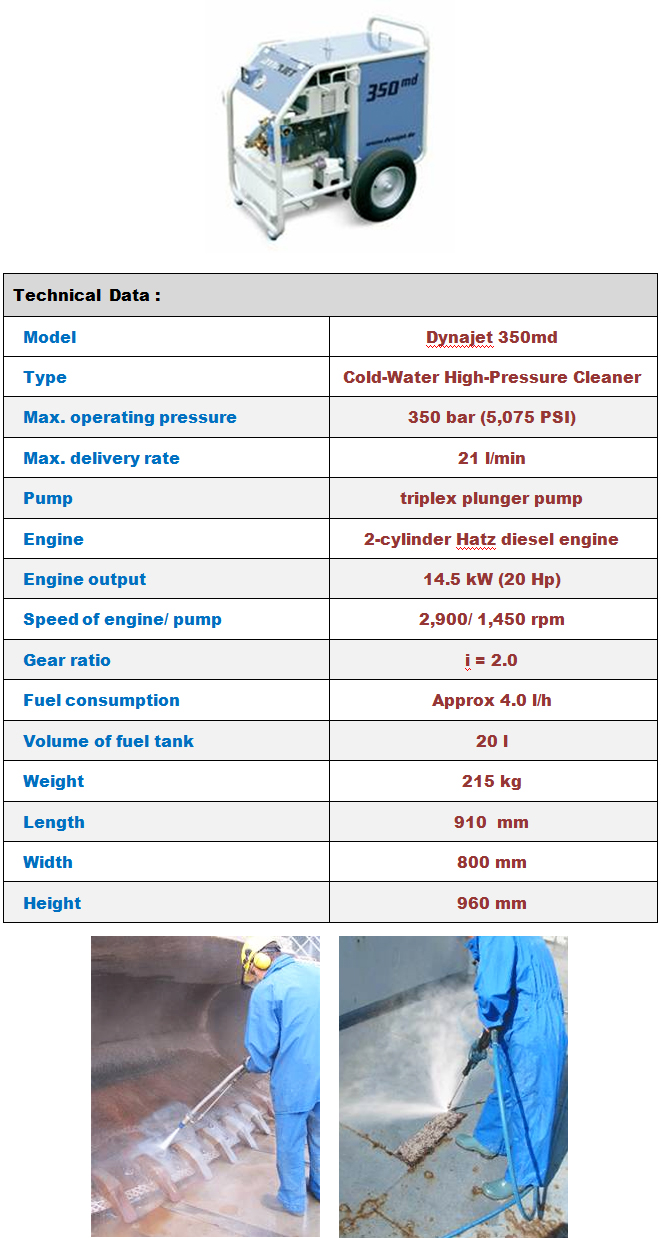

เครื่องฉีดน้ำแรงดันสูง DYNAJET ( BRAND : GERMANY) ระบบเครื่องยนต์ (ดีเซล) ให้แรงดันสูงถึง 350 bar ใช้ในงาน

DYNAJETting with a system : the powerful Dynabox 350/12 V hot-water unit, offering a working pressure of up to 350 bar (5,075 PSI), is the ideal complement for all DYNAJET trollies. Simply connect on the high-pressure side between the high-pressure cleaner and the cleaning tool and, with high-pressure hot water of up to 110°C, you’ll already be achieving results which aren’t possible with conventional cold-water systems. The other special features of the Dynabox 350/12 V are, of course, its light weight, small dimensions and its easy-loading and easy-transportation characteristics. What is more, the Dynabox 350/12 V works with a 12 V supply voltage. This means that no 230 V power cable is necessary, because the Dynabox 350/12 V can be easily connected to and operated via the combustion-driven DYNAJET trollies which are equipped with sockets as standard. Advantages

DYNAJETting with a system : the powerful Dynabox 500 hot-water unit, offering a working pressure of up to 500 bar (7,250 PSI), is the ideal complement for all DYNAJET trollies. Simply connect on the high-pressure side between the high-pressure cleaner and the cleaning tool, and, with high-pressure hot water of up to 110 °C, you’ll already be achieving results which aren’t possible with conventional cold-water systems. The other special features of the Dynabox 500 are, of course, its light weight, small dimensions and its easy-loading and easy-transportation characteristics. Advantages

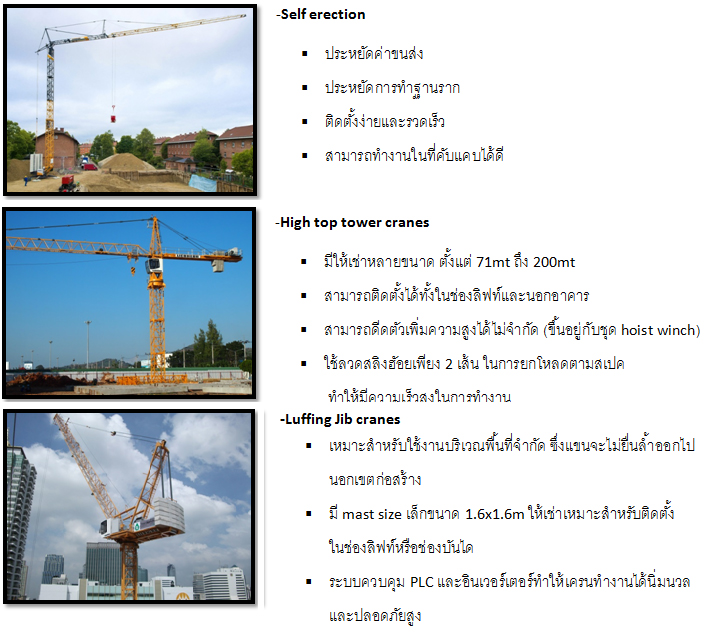

ทาวเวอร์เครนให้เช่าทุกตัวยี่ห้อ LIEBHERR ผลิตจากประเทศเยอรมันเท่านั้น มีประสิทธิภาพสูงทำงานได้อย่างรวดเร็วปลอดภัยและมี break down timeต่ำ บริษัทฯ มีทีมงานติดตั้ง-รื้อถอนที่ผ่านการฝึกอบรมจากวิศวกรจาก LIEBHERR เยอรมัน เราทำธุรกิจให้บริการเช่าทาวเวอร์เครนมาแล้วเป็นเวลาไม่ต่ำกว่า 10 ปี Please >>> Contact

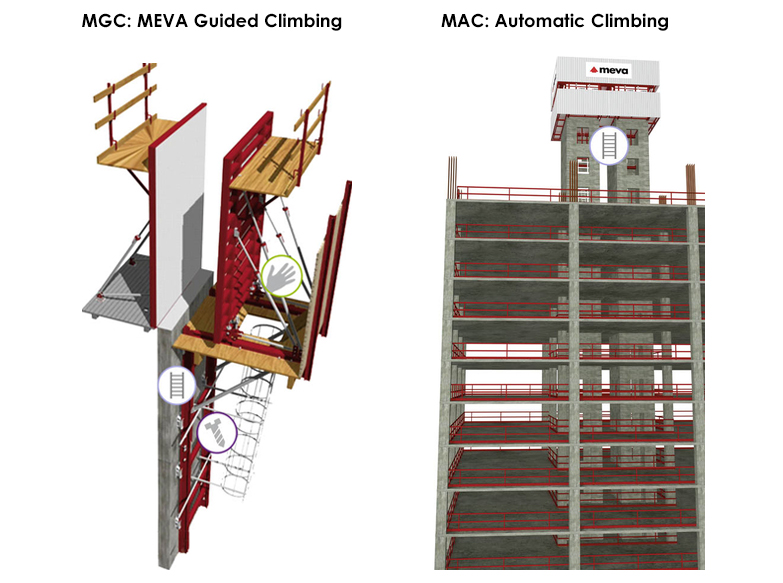

Please >>> Contact  เปิดบริการให้เช่า FORM WORK SYSTEM Please >>> Contact Meva Deck MevaDec : The All-in-One Slab Formwork  Meva Climbing Form

Please >>> Contact

Putzmeister mortar technology is a force to reckon with on both residential and non-residential construction sites the world over. As soon the structural work is complete, our products move in: from worm pumps, piston pumps, plaster spraying pumps or floor screed conveyors, we offer the most comprehensive and powerful range of plastering machines. From know-how on raw material, mix design and pumpability to jobsite logistics, Putzmeister offers customers and partners the benefit of its experience on every count: innovation, quality and service. COMING SOON   Datasheet ดาวน์โหลด PDF  OPTIMUM 8 Working high 7.7 Lifting capacity 230kg Weight 1,590kg  OPTIMUM 8 ดาวน์โหลด PDF  COMPACT 10N Working high 10.15m Lifting capacity 230kg Weight 2,190kg  COMPACT 10N ดาวน์โหลด PDF  COMPACT 10 Working high 10.15m Lifting capacity 450kg Weight 2,330kg  COMPACT 10 ดาวน์โหลด PDF  COMPACT 12 Working high 11.98m Lifting capacity 300kg (2 persons) Weight 2,470kg  COMPACT 12 ดาวน์โหลด PDF  COMPACT 14 Working high 13.85m Lifting capacity 350kg (3 persons) Weight 3,175kg  COMPACT 14 ดาวน์โหลด PDF        |